The application scope of multi-stage centrifugal pump

Multi-stage centrifugal pump, using the country recommended highly efficient energy-saving hydraulic model, with high energy efficiency, wide range of performance, safe and stable operation, low noise, long life, easy installation and maintenance, etc .; by changing the pump material, Cooling system, can transport hot water, oil, corrosive and abrasive media and so on.

D-type pump for conveying non-solid particles, the temperature is not higher than 80 ℃ of water or physical and chemical properties similar to the liquid water, suitable for mining and urban water supply and drainage works.

DG-type pump for the transport of non-solid particles, the temperature is not higher than 105 ℃ water or physical and chemical properties similar to the liquid water for boiler water or hot water delivery or similar hot water medium.

MD-type pump for conveying solid particles content of not more than 1.5% of the neutral mineral water (particle size less than 0.5 mm) and similar other sewage, the temperature of the medium is not higher than 80 ℃, suitable for steel plants, mine drainage, And other occasions.

DF-type pump for the delivery temperature of -20 ℃ ~ 105 ℃, non-solid particles, corrosive liquids.

DY-type pump used to transport solid particles whitch temperature is -20 ℃ ~ 150 ℃, viscosity is less than 120 centistokes oil and petroleum products.

- Published in Blogs

Characteristics of Multi-stage Centrifugal Pump

1.Multi-stage centrifugal pump is the vertical structure, with a small area of the characteristics of the pump center of gravity coincides with the center of the pump, which runs smoothly, vibration, long life.

2.Multi-stage centrifugal pump the same diameter and the same level in the center line, without changing the pipe structure can be installed directly in any part of the pipeline, the installation is very convenient.

3.Motor plus rain cover can be placed directly outside the use, without the need to build the pump house, significant savings in infrastructure investment.

4.Multi-stage centrifugal pump head can change the pump series (number of impellers) to meet the different requirements, so a wide range of applications.

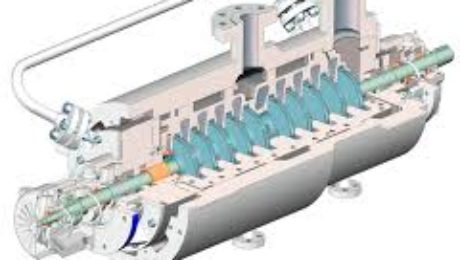

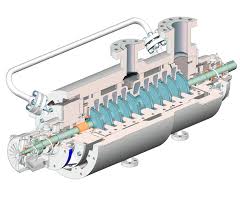

Multi-stage centrifugal pump structure

5.Shaft seal with carbide mechanical seal, reliable sealing, no leakage, mechanical damage.

6.Energy efficient, beautiful appearance.

- Published in Blogs