Wear protection

Impeller wear and abrasive composition, particle size, concentration, shape, impact speed, impact angle, the chemical composition of the gas, nature, temperature and humidity and other factors. While the uneven flow of gas within the impeller speed up the wear and tear.

As measures to prevent impeller wear: First, reduce the dust and corrosive gases into the fan, this fan must have to run the system transformation; the second is to try to make local wear uniform wear and tear, which need to improve the wear resistance of the impeller . If you improve the wear resistance of the impeller can be used high hardness and good wear resistance of the material. This is not only difficult for the impeller manufacturing process, but also from an economic point of view is unreasonable. Therefore, it is an economical and reasonable solution to improve the surface quality of the impeller, wear-resisting layer on the serious parts of the impeller wear and spray a layer of liner on the blade in order to achieve wear resistance.

- Published in Blogs

How Water moves in the impeller

Water in the impeller is in composite movement, that is, on the one hand it should follow the leaf working surface outward swimming, on the other hand it should adjust the rotation with the impeller. The former is called the relative movement, its speed is called the circular motion, its speed is called the peripheral speed, uses u to indicate. The synthesis of two kinds of movement, that is, the absolute movement of water within the pump, the speed of that V said.

When the impeller is working, the movement of any point on the radius of the liquid state can be expressed by the size and direction of the three speed, composed of these three speed graphics called speed triangle. When studying pumps, it is important to understand the fluid flow at the inlet and outlet of the impeller, so generally only draw the inlet velocity triangle and the exit velocity triangle.

- Published in Blogs

Large Pump industry has great prospects with the policy impact

Pump industry is a typical investment-driven industries, market demand under the national macro-policy, especially the water conservancy, construction, energy and other macro-policy impact.

In the domestic casting industry development process, the valve casting enterprises should address energy-saving electricity, labor shortage, national policies and other issues, while more concerned about the development of the industry changes, and in accordance with their own operating conditions appropriate adjustments in order to better the future Fast development.

With the continuous progress of technology, pump products will be intelligent direction, to pressure, flow, temperature and vibration parameters such as monitoring; to pump shaft, bearing and sealing conditions to assess; to the cause of the failure Such as diagnosis. Magnetic pump, diaphragm pump technology will focus on the development of the industry in the design of electronic control system, improve the drive and the search for new materials and so on.

Data show that investment in sewage treatment equipment, water pumps, machinery and equipment accounted for about a total investment of 15, according to the proportion of calculation, during the second five urban sewage treatment pump products in the field of demand will be 600 billion yuan in the next three years There are nearly 40 billion market demand, the market prospects. In the near future, China’s valve key enterprises will be able to catch up with and surpass similar foreign enterprises, the country’s major technology and equipment to contribute to the domestic market in the world pump valve competition in the share of a certain world and become the world valve manufacturing Of the country.

- Published in Blogs

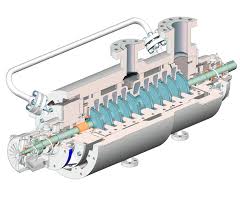

The application scope of multi-stage centrifugal pump

Multi-stage centrifugal pump, using the country recommended highly efficient energy-saving hydraulic model, with high energy efficiency, wide range of performance, safe and stable operation, low noise, long life, easy installation and maintenance, etc .; by changing the pump material, Cooling system, can transport hot water, oil, corrosive and abrasive media and so on.

D-type pump for conveying non-solid particles, the temperature is not higher than 80 ℃ of water or physical and chemical properties similar to the liquid water, suitable for mining and urban water supply and drainage works.

DG-type pump for the transport of non-solid particles, the temperature is not higher than 105 ℃ water or physical and chemical properties similar to the liquid water for boiler water or hot water delivery or similar hot water medium.

MD-type pump for conveying solid particles content of not more than 1.5% of the neutral mineral water (particle size less than 0.5 mm) and similar other sewage, the temperature of the medium is not higher than 80 ℃, suitable for steel plants, mine drainage, And other occasions.

DF-type pump for the delivery temperature of -20 ℃ ~ 105 ℃, non-solid particles, corrosive liquids.

DY-type pump used to transport solid particles whitch temperature is -20 ℃ ~ 150 ℃, viscosity is less than 120 centistokes oil and petroleum products.

- Published in Blogs

Characteristics of Multi-stage Centrifugal Pump

1.Multi-stage centrifugal pump is the vertical structure, with a small area of the characteristics of the pump center of gravity coincides with the center of the pump, which runs smoothly, vibration, long life.

2.Multi-stage centrifugal pump the same diameter and the same level in the center line, without changing the pipe structure can be installed directly in any part of the pipeline, the installation is very convenient.

3.Motor plus rain cover can be placed directly outside the use, without the need to build the pump house, significant savings in infrastructure investment.

4.Multi-stage centrifugal pump head can change the pump series (number of impellers) to meet the different requirements, so a wide range of applications.

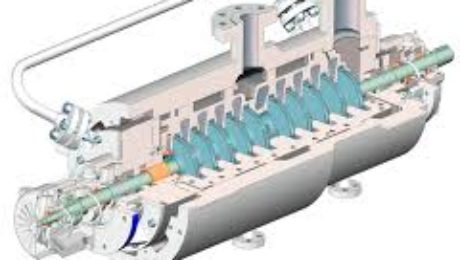

Multi-stage centrifugal pump structure

5.Shaft seal with carbide mechanical seal, reliable sealing, no leakage, mechanical damage.

6.Energy efficient, beautiful appearance.

- Published in Blogs

What is the Meaning of the “Stage”of Multistage Centrifugal Pump

Most people may not understand the “stage”of multistage centrifugal pump. Now i will share the meaning with you.

In multistage centrifugal pump,the “stage” is composed of impeller which with deflector (such as guide wheel annular or volute casing pump).

Multistage centrifugal stage is typically characterized by: a power transfer from the shaft to the carriage of the media. As long as there are no side effects of feed conditions or effective cavitation margin value. With these two values can be drawn level efficiency. Multistage centrifugal stage efficiency is by all strive to achieve the level of constant value as high as possible.

Multistage centrifugal pump to determine order of magnitude, to ensure that each stage (the impeller configuration) have the appropriate torque ratio. Here, to a single impeller, the most important thing is not multi-stage pump specific speed, but the speed which related to stage.

Welcome to visit our site to learn more if you want to understand the characteristics or more.

- Published in Blogs

Vibration Analysis of Centrifugal Pump

- The centrifugal pump rotor unbalance and misalignment. This problem centrifugal pump vibration problems in a larger proportion, about 80 per cent. Centrifugal rotor unbalance factors: material to prevent uneven parts substandard, resulting in mass of the rotor shaft centerline do not coincide with the center line of eccentricity according unbalanced formation. Centrifugal pump rotor unbalance correction can be divided into two. Static and Dynamic Balancing: balance and generally referred to as single-sided double-sided balance. The difference is this: on one side is balanced by correcting the balance in a positive school, while the balance is in two-sided surface correction correction.

- Install Reason: loose foundation bolts, level of school transfer is not adjusted before the centrifugal work, to check its foundation bolts are loose phenomenon, as well as the installation of a centrifugal pump is horizontal. These conditions can also cause the occurrence of centrifugal vibration at work.

- Aforeign body in the centrifugal pump. Before centrifugal pump, the internal pump to check the next, due to the long-term use, there may be some weeds such as water and other foreign matter inside the centrifugal pump.

- Due to prolonged use of centrifugal pump cavitation caused by perforation.

- The presence of the unreasonable design , such as part sizes and other issues. However, this situation is relatively small. Centrifugal pump at the factory, in the workshop will be multiple internal testing work to ensure that the passing rate of the factory Centrifugal Pump.

- Published in Blogs

Matters need attention when use centrifugal pump

Centrifugal pump is a vane pump, relying on rotating impeller during rotation, due to the interaction between the blades and the liquid leaves the mechanical energy transmitted to the liquid, the liquid can increase the pressure to achieve the purpose of transmission fluid. Centrifugal pump starting need pay attention to four points:

1.Head at a certain speed centrifugal pump produced under a defined value. Flow and shaft power operating point depending on the unit system connected to the pump case (difference, the pressure difference and line losses). Lift with the flow rate changes.

2.Stable, continuous delivery, flow and pressure pulsation.

3.Generally no self-absorption capacity, the need to pump the liquid filled or evacuated after pipeline to start.

4.Centrifugal valve in the discharge line to start off, vortex flow and axial pumps in the valve is fully open state to start to reduce the starting power.

Because centrifugal impeller centrifugal force is formed by vacuum suction to lift the water, so that when the centrifugal pump starts, you must first close the valve, irrigation. Water level exceeds the portion above the impeller, centrifugal pump exhaust air before you start. After starting to form around the impeller vacuum to suck up the water, which can automatically open the valve, the water lifted. Thus, the valve must be closed.

- Published in Blogs

How to regulate the flow of centrifugal pump

(1)Change the opening of the valve

Change the valve switch on the centrifugal pump outlet line, and its essence is to change the pipeline characteristic curve. As shown below, when the valve off hours, increased local resistance line, pipeline characteristic curve steepens, the operating point move by the M M1, flow from the QM reduced to QM1. When the valve is opened wide, the line resistance is reduced, the pipeline characteristic curve becomes flatter, the operating point moves to M2, the flow increased to QM2.

Valves regulate the flow quickly and easily, and traffic can be continuously changed, suitable for continuous production of chemical characteristics. It is widely used. The disadvantage is that the valve off hours, increase the resistance loss, increased energy consumption, very economical.

(2) Change the speed of the pump

Change pump speed substantially change the pump characteristic curve. The original pump speed n, operating point M, as shown below, if the pump speed increased to n1, the pump characteristic curve H – Q move up, move the operating point by the M M1, increased flow from the QM to QM1. If the pump speed falls n2, the operating point moves to M2, flow down to QM2.

This adjustment method requires expensive transmission gear or the prime mover, and it is difficult to achieve continuous adjustment of flow, so rarely used in chemical production.

So it is important to use centrifugal pump correctly.

- Published in Blogs

Various losses of centrifugal pump

(1) volume loss

Losses due to leakage caused by the pump referred to volume loss. When no volume loss of power when the pump and the pump volume loss ratio of the power called pump volumetric efficiency.

(2) hydraulic losses

Fluid flow through the impeller, the pump housing, there is a change of flow rate and inverse pressure gradient magnitude and direction of the circulation and cause vortex, resulting in energy loss, this loss is called hydraulic losses. Rated flow centrifugal pump hydraulic efficiency generally 0.8 to 0.9.

(3) mechanical loss

And the bearing friction loss, seal, etc. of high-speed rotating mechanical friction between the impeller and the liquid called mechanical losses caused.mechanical efficiency is generally 0.96 to 0.99.

- Published in Blogs