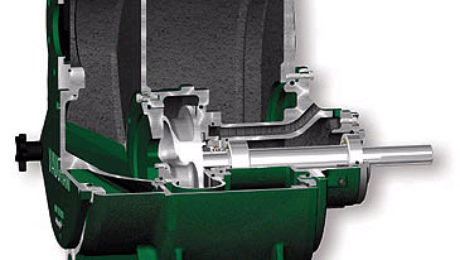

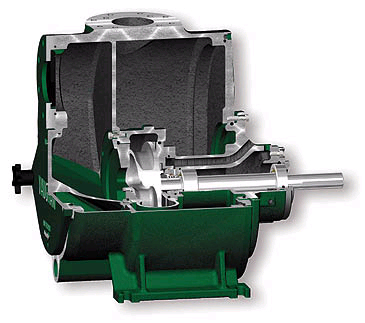

Current situation of self-priming centrifugal pump

With economic development, self-priming centrifugal pump more and more widely used in the project.

For self-priming centrifugal pump, because of its simple installation, small footprint, easy maintenance, no noise, etc., are widely used in municipal engineering projects, factories, businesses, hospitals, hotels, residential areas and other sewage discharge. At present, China’s domestic self-priming centrifugal pump is mainly composed of domestic manufacturers production and manufacturing, small part of the products imported from abroad. Market prospects. However, due to the reliability of the sewage pump needs to be strengthened, therefore, improve the technological content of their products is the main direction of future development of the firm.

- Published in Blogs

Application scope of self-priming sewage pump

Self-priming sewage pump as compared with similar domestic products, it has a simple structure, self-priming performance, sewage capacity, energy efficient, easy maintenance, etc., is a national initiative in sewage pump series products. The technical performance indicators in the leading domestic and reached the international advanced level, with broad application market and development prospects.

1. Ambient temperature ≤45 ℃, medium temperature ≤60 ℃.

2. The medium of cast iron pumps PH value of 6 to 9, stainless steel pump is 1 to 14.

3. Through the particle diameter of 60% of the pump diameter, fiber length of 5 times the diameter.

4. The total weight of impurities in the medium does not exceed 15% of the total weight of the medium, medium weight does not more than 1240 kg /m³

- Published in Blogs

Advantages and applications market of self-priming sewage pump

For any individual product, there are maybe many shortcomings, but no matter, it will one to two advantages. As the outstanding products, then there will be more than a luminous point, then, for self-priming sewage pump, what advantage it have?

1.Good performance

Compared to general products, it is self-priming to a height more than 1 meter, it is commendable that higher self-priming height will cost less time.

2.Good sewage capacity

For sewage pump,the most worried about is clogged, once clogged, it will seriously affect the work efficiency. But self-priming sewage pump is designed with the professional anti-blocking devices, the possibility of clogging can be reduced to a minimum .

3.Green energy

Energy savings actually a problem we must pay attention. The self-priming pump has advanced hydraulic devices, relatively than ordinary products, in terms of power increased by 3 to 5%, Do not underestimate this figure, it can save a lot of money indirectly.

Because it has so many advantages, so its use will be more extensive and professional, chemical, petroleum, pharmaceutical, mining, paper, fiber, pulp, textile, food, power plants and municipal sewage works, public facilities, sewage, river pond breeding and so on,all use self-priming sewage pump.

- Published in Blogs

How to maintain self-priming sewage pump

1.Check the tubing and junction of self-priming pump with or without loosening. Hand or tool to turn the pump, and check if sewage pump is flexible.

2.Try to control the inner self-priming pump flow and head on the plate indicated range to ensure self-priming pump operating at maximum efficiency point in order to obtain maximum energy savings.

3.When self-priming pump during operation, the bearing temperature can not exceed the ambient temperature of 35℃, the maximum temperature can not exceeding 80℃.

4.If self-priming pump has abnormal sound, it should be stopped immediately to check the reason.

5.To stop using sewage pump, turn off the valve, pressure gauge, and then stop the motor.

6.If self-priming sewage pump will not work in a long time or work in the winter season, after parking, the need of the lower pump drain plug unscrew the media put the net. Prevent cracking. (If sewage, please clean chamber with water)

7.Carefully listen to the motor running to check if sound is usual, because the runtime engine room noisy, by means of a screwdriver or listen rods and other aids, posted pro motor ends listen, if you often listen to, not only find motor and trailer bad vibrations moving equipment, even the inside of the bearing can determine how much oil is so timely add oil bearing, or replaced with new bearings and other appropriate measures to deal with, to avoid motor bearing short of oil and dry grinding stall, walk cylindrical, sweep chamber burned.

- Published in Blogs

Why self-priming sewage pump’s motor is hot?

In the process of self-priming sewage pump,if motor is too hot will cause tripping and stopping. The main reasons are as following:

1. Ultra-current, actual head reach, fluid overload, causing the motor load. Solution: install valve in the pump outlet, the valve off a small reduction in traffic.

2. Soaking of motor lead wet; solution: drying damp motor.

3. The supporting motor power is small; Solution: Adjust support, replace the motor.

So it is important to maintain self-priming sewage pump.

- Published in Blogs

Improve quality, optimize service, perfect after-sale!

Commitment to product quality

We guarantee that the goods supplied are high quality products, using first-class technology and the best materials made of, and in full compliance with national, industry, enterprise standards prescribed or contract technical conditions to ensure the equipment has been installed correctly, the normal operation and maintenance, having a satisfactory performance in its useful life. After completion equipment manufacturing, equipment quality and performance requirements detailed and comprehensive inspection of the relevant provisions of the standard contract and that quality to meet the demand side, and issue a product quality certification.

Site inspection and acceptance

Equipment installation, According to the requirements, the company will appoint engineers to guide test equipment operation and inspection, if the test device was found because of quality problems leaving the original equipment performance and technical requirements of a deviation, the company responsible for resolving. If necessary, repeat the test until you meet the requirements.

Installation Instructions Service

Equipment installation should be detailed construction drawings were prepared by the Company. The company provides supervision and guidance during the installation process, responsible for identifying equipment installation is complete, the device can only be confirmed before the next step of the commissioning phase.

Operation and commissioning guide

After the installation is complete, the Company will supervise the demand side, until the implementation of trial operation, jointly responsible and demand-side test plan and test engineering guidance.

Site technical services

In order to successfully make the equipment put into operation, the company appoint skilled, qualified technical personnel to the scene to conduct technical services.

- Published in Blogs

Arrangement and requirements of pump

Technically there are certain requirements and technical specifications:

First, arrangement requires

(1) For open or semi-open layout of the pump, the pump and prime mover in general and the axis perpendicular to the axis of the pipe gallery.

(2) For the interior layout of the pump, when the temperature is higher than its transport liquid natural point or transmission fluid is a liquid hydrocarbon, the pump should be disposed with other miscellaneous separately within their respective rooms, separated by a firewall.

When the pump is disposed in the interior, it is generally not considered prevailing requirements of motor vehicle maintenance.

Spacing between the pump should not be the end or side of the pump and the wall is less than 1.2 ~ 1.5m, spacing between two rows of the pump should not be less than 2m. Power side and the side of the steam reciprocating pump pump should be left out of the piston and rod position.

Vertical pumps arranged in the bottom of the tube side porch or framework, the top of the pump should be set aside space for the installation and maintenance needed.

Various centrifugal pump maintenance inspections required space. When piping on both sides to set aside at least one side of the pump used to do maintenance.

Second, the arrangement of pump

(1) Open layout generally concentrated pump disposed in the tube side or a side porch, can also be arranged in the vicinity of the suction miscellaneous equipment, the main advantage is well ventilated, easy operation and maintenance. If the pump is disposed miscellaneous pipe porch side pump outlet center line should be aligned from the pipe centerline pillars 0.6m.

(2) Semi-open semi-open arrangement arranged pump is suitable for rain-fed areas, usually in tubes arranged side porch pump, located in the upper part of the pipe roof. Or the pump is disposed on the lower surface of the frame to frame as the platform roof. The pump arrangement requirements, the pump is arranged in a single row, double or multiple rows.

(3) Arranged in the interior layout of the interior pump suitable for cold or sandy areas, as well as process the special requirements of the occasion.

- Published in Blogs

Why the efficiency of pump decreased?

1.Due to water erosion, water pump impeller and the inner wall of the flow path through the water became rough, the friction coefficient of the pump flow path increases, and in the pump flow rate greatly increased and the head of water loss. Hydraulic efficiency.

2.Since the drugs before dosing pump or water quality and other reasons, so that the pump housing severe fouling or corrosion. Severe fouling pump housing can increase the casing wall thickness of about 2ram, dirt and water pump wall to form tumors, so that the pump volume reduced, reducing the amount of pumping, and the flow path coarse, increase head loss. Customer product efficiency and hydraulic efficiency is reduced.

3.Casting defects caused due process pumps, cavitation, erosion, corrosion and chemical attack and other causes produce the pump flow passage holes or cracks, resulting in water flow caused by vortices of energy loss. Hydraulic efficiency.

4.The surface of the impeller cavitation. Due to the dorsal surface of the blade run negative pressure, when the pressure Pk <Pva when, after generating steam hole and cellular surfaces, in the electrochemical corrosion effect, leaves the pump cavitation.

5.The volume loss and mechanical loss. Since the pump using a long time, and resistance to mechanical wear and tear resulting leakage increases, the volumetric efficiency and mechanical efficiency.

For these reasons, the pump performance deteriorates. Operating efficiency is reduced by 2 to 5%, the efficiency of pump can be severely reduced by more than 10%.

- Published in Blogs

OTHER ENTERPRISES

Volkswagen of Shanghai

Shanghai Dupont

The food Co.,Ltd.of McDonald of Beijing

Tianjin Smath Kline & French Laboratones Ltd

The chemical fibre of Yizheng

Farm of Daxing of Heilongjiang

Shanghai She Shan international golf club Co., Ltd.

Reach high papermaking Co., Ltd. majestically in Guangzhou

Flat south fish’s peak cement limited company of Guangxi

Fujian Nan Ping paper industry Co., Ltd.

Lekai film group company

International cooperation Limited Company of Dalian ,etc.

- Published in Blogs

ELECTRIC POWER SYSTEM

About Project:

The nuclear power station of Daya Gulf

The Ge 's

Winding power plant of China of country of Tianjin

Thermoelectric Co., Ltd. of environmental protection of port of Yangzhou

Suzhou Su Zheng thermoelectric Co., Ltd.

North logical sequence harbour power plant of Zhejiang

Reach and draw the special power plant in Inner Mongol

Nuclear power Company of Qinshan

Shanghai Wujing Power Plant

Heat and power plant of emperor’s aunt of Shenyang

Huangshi power plant ” heavy to take the place of ” technological transformation project wait for “little “,etc.

- Published in Blogs